Designed for Blinkit, India’s leading quick-commerce platform with 20M+ monthly users.

![[Mockup] iPhone 17.png](https://static.wixstatic.com/media/36c116_d7afebb9a301473f951133230751949b~mv2.png/v1/crop/x_0,y_15,w_1107,h_1515/fill/w_293,h_401,al_c,q_85,usm_0.66_1.00_0.01,enc_avif,quality_auto/%5BMockup%5D%20iPhone%2017.png)

![[Mockup] iPhone 19.png](https://static.wixstatic.com/media/36c116_47506681d1644db3817fbfebf69f6e67~mv2.png/v1/crop/x_7,y_15,w_1092,h_1491/fill/w_293,h_400,al_c,q_85,usm_0.66_1.00_0.01,enc_avif,quality_auto/%5BMockup%5D%20iPhone%2019.png)

17.2% increase in items picked per hour and reduced dependency on QC

PROBELM

What are we trying to solve and why?

Quick commerce warehouses store inventory in bulk, and picking speed is important to fulfill dark stores on time.

The previous store-level picking forced pickers to cover long, fragmented routes while picking multiple SKUs in small quantities. This increased physical effort, slowed picking, and made QC mandatory before dispatch.

SOLUTION

How did we solve this?

We introduced Item-Level Picking, allowing pickers to collect items for multiple stores in one go from fewer locations to optimize pickers pick path. This is followed by Put to Light (PTL) segregation to guide accurate store-wise sorting. This shifted accuracy checks upstream and reduced reliance on manual QC.

USERS

Pickers

Transporter

Segregator

Proof that the solution worked!

17.2%

Increase in items picked per hour per picker, improving overall picking efficiency and optimizing pick path

25%

Reduction in segregation errors eliminating the need for additional QC step due to less picking errors

60%

Increase in overall productivity, driven by combined effect of Item level picking and PTL based segregation

ROLE AND TEAM

Product Designer

MY ROLE

2 Months+

DURATION

1 Designer, 1 PM, 8+ Engineers

TEAM

Led the design process by understanding user needs, mapping workflows, crafting interface, and collaborating with PMs, engineers, and on ground operations team to optimize warehouse processes.

SYSTEM UNDERSTANDING

Warehouse process overview

High-level overview of how inventory moves from racks to dispatch lanes, highlighting where picking, segregation, and QC sit in the flow.

STORE - LEVEL PICKLIST

How did the previous workflow work?

Previously, picklists were generated at a store level, pickers collected multiple SKUs in small quantities across multiple locations for one store X dispatch time.

Where did store-level picking process break?

The above image is of a store level pick list task. The user is expected to pick 38 SKUs and 44 Units in a single pick list. This would most likely require the picker to go to at least 25 - 35 different locations to pick 44 units.

ISSUES

Pick Path and Time

Pickers covered 25–35 locations per picklist, increasing effort and time.

Picking Errors

Increase in picking errors due to picking multiple SKUs at a time.

QC Dependency

High dependency on QC to check errors in picked quantity

PROBLEM STATEMENT

Store-level picking workflow increases physical effort and error rates, slowing fulfillment and creating a QC bottleneck that limits warehouse throughput.

PROPOSED SOLUTION

To enable Item-Level Picking and introduce PTL segregation

Pickers will now collect bulk quantities of 1- 3 SKUs from nearby locations for multiple stores in one go instead of hunting down 30+ SKU-location combinations per store. Store wise segregation of the picked quantity will be handled downstream using PTL to pigeonhole racks.

ITEM LEVEL PICKLIST

V1: PIGEONHOLE SETUP

Pigeonhole rack system created at Bangalore warehouse to test the system before getting PTL

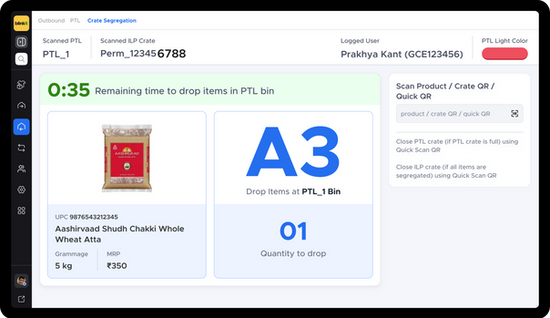

V2: PUT TO LIGHT (PTL)

PTL (Put to Light) uses light displays, indicating the specific locations where items need to be placed or "put" after being picked.

Users and their workflows

Pickers

Bulk picking from fewer locations, reducing movement and cognitive load.

Transporter

Scans crates at the spiral chute and routes them to QC or PTL station based on crate type.

Segregator

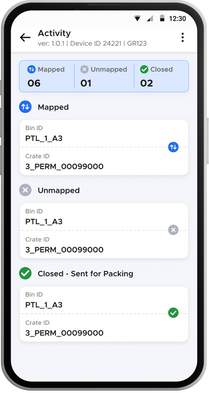

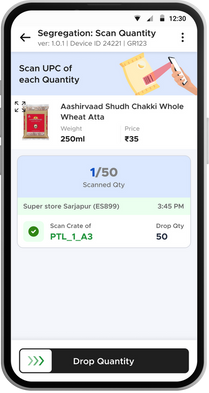

Guided by PTL prompts to drop exact quantities into store-wise bins, eliminating manual checks.

TRANSPORTER WORKFLOW

Designing for real picking behavior and operational limits

Assigning an IPST Zone

At the spiral chute exit, transporters assign themselves to an IPST zone and scan incoming crates dropped by pickers.

User scans IPST zone → Scans all crates

Process on ground?

Transporters work with two pallets: one for store-level crates and one for item-level crates. After scanning, each crate is placed on the assigned pallet and moved to its destination station.

On-screen instructions guide the transporter on where to move every crate.

![[Template] iPhone 16.png](https://static.wixstatic.com/media/36c116_4e0a5e714ff44bca9fba02567f8c8ac6~mv2.png/v1/fill/w_249,h_466,al_c,q_85,usm_0.66_1.00_0.01,enc_avif,quality_auto/%5BTemplate%5D%20iPhone%2016.png)

Transporter scans store level crate

![[Template] iPhone 17.png](https://static.wixstatic.com/media/36c116_cf1b2ad3e2b94b499bda93033118506e~mv2.png/v1/fill/w_249,h_466,al_c,q_85,usm_0.66_1.00_0.01,enc_avif,quality_auto/%5BTemplate%5D%20iPhone%2017.png)

Transporter scans Item level crate

![[Template] iPhone 18.png](https://static.wixstatic.com/media/36c116_8cb1502d7b3b4a8fa7d642749d8c89c8~mv2.png/v1/fill/w_249,h_466,al_c,q_85,usm_0.66_1.00_0.01,enc_avif,quality_auto/%5BTemplate%5D%20iPhone%2018.png)

All scanned crates

Why have an interface for a repetitive task of scanning crates, especially when a screen adds friction to the flow?

The initial idea was to use color-coded crates (yellow for item-level, blue for store-level) instead of a screen to simplify the task of transporter. However, this was not feasible due to the cost implications and the high volume of crates needed daily, which would have blocked picking if procurement fell short due to continuous movement of crate in and out of warehouse.

SEGREGATOR WORKFLOW

Workflow for Segregator with Pigeonhole setup

Once the crates are transported to the segregation (PTL) area, the segregator has to pick any crate and start segregating items based on store. User can start with any item they see first in the crate.

Pigeonhole setup for testing

Once an item variant is selected, the segregator drops items into mapped store crates. On scanning an item, the system already knows store-wise quantities and directs exactly where and how many units to drop.

User scans PTL station → Scans any crate → Scans any item and selects item variant

Mirroring PTL grid on UI

The UI mirrors the physical PTL grid and highlights the target cell for each drop to guide spatial movement.

Dropping one unit at a time eliminates the need for downstream QC.

Dropping all quantity of store

Store quantities are shown upfront using bold grid numbers, reducing UI complexity and enabling faster builds and pilots.

![[Template] iPhone 19.png](https://static.wixstatic.com/media/36c116_1e6f955bba494871aef055809dbc4193~mv2.png/v1/fill/w_249,h_466,al_c,q_85,usm_0.66_1.00_0.01,enc_avif,quality_auto/%5BTemplate%5D%20iPhone%2019.png)

![[Template] iPhone 20.png](https://static.wixstatic.com/media/36c116_ee6d711240a8400fa4357bfb01f09194~mv2.png/v1/fill/w_249,h_466,al_c,q_85,usm_0.66_1.00_0.01,enc_avif,quality_auto/%5BTemplate%5D%20iPhone%2020.png)

Approach 1

Approach 2

Evolving to PTL setup based on learnings

PTL setup + Ring scanner

After validating the pigeonhole setup for item-level picklists and PTL-based sortation, we introduced a ring scanner to remove dependency on handheld devices.

The pigeonhole grid was replaced with a PTL setup, where lights guide each drop. A TV screen supports only secondary instructions and error handling.

EDGE CASES

Designed to handle failure on ground

All failure states are handled using popups that explain what went wrong and guide the user on the next action.

This keeps the segregator inside the scanning flow and avoids supervisor dependency.

Early explorations and trade offs

Testing and Impact

Launched item-level picking for a few SKUs and pigeonhole segregation in 1 warehouse for testing.

Seeing its benefits, we introduced a proper PTL setup with a ring scanner.

Next, we plan to roll out an advanced PTL setup across all warehouses.

Metrics to prove the effectiveness of Item level picking and PTL

17.2%

Increase in items picked per hour per picker, improving overall picking efficiency and optimizing pick path

25%

Reduction in segregation errors eliminating the need for additional QC step due to less picking errors

60%

Increase in overall productivity, driven by combined effect of Item level picking and PTL based segregation